Auke Visser's International Esso Tankers site | home

GIANTS IN PORT

Source : Esso Singapore News February 1981.

The Esso Hawaii is a giant.

From bow to stern, it is the size of about three football fields with a capacity of 280,000 deadweight tons. The other day we came

face to face with it, drydocked in Mitsubishi Singapore Heavy Industries’ shipyard in Jurong.

It had been there about nine days.

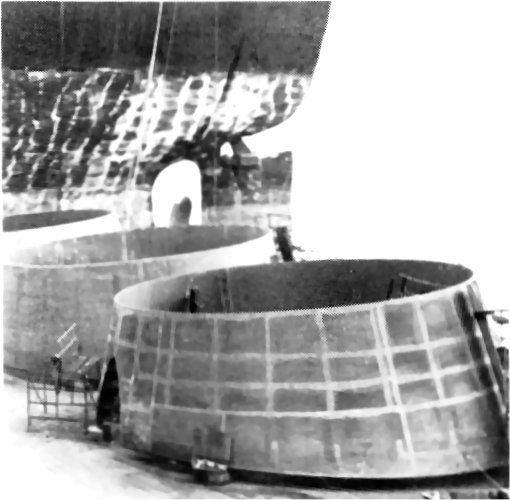

New propeller ducts before installation. They are made in Japan and specially towed down to Singapore.

For repairs, for a new paint job worth about a million dollars, and for the installation of a new propeller duct, specially towed in from Japan, that will increase propulsion efficiency.

Esso Hawaii is a VLCC (Very Large Crude Carrier) and carries Exxon’s crude oil primarily from the Persian Gulf to Europe.

lt is one of 20 Exxon-owned vessels which will be coming to Singapore for repairs and modi?cations this year.

Once fitted the ducts help increase propeller efficiency and save energy.

Of these 20 ocean-going vessels, 16 (including the Esso Hawaii) are VLCCs. Other local shipyards to be used for repairs are Jurong Shipyard, Hitachi Zosen Robin Dockyard and Keppel Shipyard.

Besides undergoing routine repairs, Exxon’s vessels will be modified with the installation of new propeller ducts, improved crude washing systems and satellite communications system.

Last year, a total of 22 Exxon ocean-going vessels were repaired and modified in Singapore’s shipyards at a total estimated cost of S$46 million.

This brings to 106 the number of vessels brought here by Exxon for repairs and modifications in the six years to 1980.

|