Auke Visser's International Esso Tankers site | home

First American Arcform Tankers - Part-6

Source : Marine Pacific Review, Volume 33, January, 1936.

Tank Cleaning System

The Butterworth tank cleaning system will he installed. This system consists of a saltwater heater located in the engine room and connected to the fire main and to one or more portable Butterworth machines. Each cargo tank has one or more special manholes arranaged to accommodate one of these machines which is a special type of oscillating spray nozzle. The fire pump drawing sea

water discharges it through the heat- er into the fire mains at a pressure of 200 pounds per square inch and a temperature of 180 degrees Fahren- heit. The Butterworth machine is inserted through the manhole and connected by a section of a special high

pressure hose to the nearest fire main outlet.

This system has given very satisfactory results in a number of tankers and is fast becoming American standard practice for tank cleaning.

Windlass and Steering Gear

The windlasses and steering gears are of the Hyde Windlass Company’s make.

The Windlass is of the spur geared type driven by electric motor selfcontained on same base plate. The two wildcats on Windlass were designed for handling 21/8-inch cast steel chain; each wildcat has independent locking gear and brake band controlled by means of hand wheel.

Large Warping gypsies are fitted on ends of intermediate shaft. The electrical equipment consists of a marine type motor fitted with a shoe type brake. The control consists of a water tight master switch and a magnetic panel.

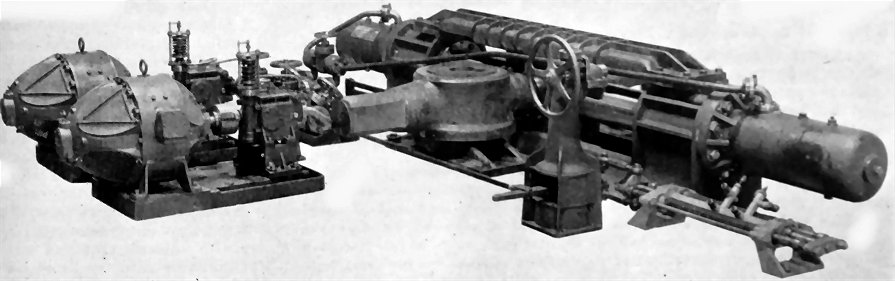

Above: Hyde electro-hydraulic steering gear for tanker R. P. Resor.

The steering gear is of the hydro electric type and consists of a cast steel tiller for rudder stock Working in a swivel bearing supported in the double plunger. The two hydraulic cylinders and plunger are self-contained on one base plate. There are two power units; each consisting of a constant speed motor directly coupled to a variable stroke pump which forces oil through tubing

under pressure of around 800 pounds to the cylinders of steering gear. A set of valves at each pump provides means for quick changeover from one pumping unit to the other. The steering gear has automatic control with an emergency wheel at the steering gear as well as the usual wheel at pilot house and bridge stations.

A Brown type hydraulic telemotor serves as a means of transmission between the steering stations forward and the steering gear. The telemotor transmitter is located in pilot house fitted with steering wheel and the receiver aft at steering gear connected to the automatic follow-up.

There are two lines of copper tubing about 1/2-inch diameter which extend from forward aft connecting the telemotor transmitter to the receiver cylinders. This telemotor system is charged with a mixture of water and glycerin, or telemotor oil.

Deck Winches

Three Lidgerwood winches are used, one forward, one amidship and one aft. Each winch is capable of lifting a load on either winchhead, but not simultaneously, of 16,000 lbs. at 40 feet per minute.

Each winch has two winchheads 20 inches diameter, 20 inches face, with 24-inch diameter flanges. These winchheads are of cast iron with cast whelps, keyed to the winch shaft.

The winch shaft is of special high carbon steel, accurately machined and supported in bronze bearings.

There are two gear reductions between the electric motor and the winchhead shaft, with the gears of cast steel and the pinions of forged steel, all gearing having machine cut teeth. All gearing is totally enclosed in an oil tight housing, the lower part of the housing being cast integral with the bedplate and supporting the winch shaft and intermediate shaft bearings. This housing, together with the bedplate, is of special cast iron. The housing cover is of cast iron bolted to the housing and equipped with hand hole covers for

insertion of lubricant and inspection. The electric motors are 25 horse- power, 230 volts, direct current,Type TE, watertight. Each motor is fitted with a watertight solenoid brake.

The drum controllers are watertight, reversing with five points in each direction. The protective panel is dripproof with jam relay, overload and low voltage protection. The motors were manufactured by the Diehl Manufacturing Company, and the brake and controls by Cutler Hammer Manufacturing Company.

All of the wiring, piping and fit- tings are of the highest grade materials and are inspected carefully to meet the rigid specifications of the Standard Oil Company. All valves on the oil lines are Crane Double Disc Gate Valves of the standard iron body, brass mounted, flanged end type with hand hole clean outs.

These valves are rated for 200 pounds per square inch pressure, cold oil. A car load of 6-, 8-, 10-, and 12-inch sizes of this type valve was used on the two tankers.

Officers’ and Crews‘ Quarters

Captain's suite (office, bed room, and bath) is located on the upper bridge deck. The erection on this deck houses also the radio room, radio operator’s bedroom, and master gyro compass room. On the bridge deck immediately below are rooms for the first, second, and third officers, a bathroom and two spare bedrooms for owner and or guests.

On the boat deck aft are: an office and a bedroom for the chief engineer; bedrooms for first, second, and third assistant engineers; a bedroom for the steward; two wash rooms, a bath room, and a hospital.

On the poop deck below are: the ship's galley and pantry; mess rooms for the officers, the petty officers, and the crew; two wash rooms each with toilet and shower;and four bedrooms for, four boys, two cooks, a pump man and a boatswain, and an electrician and a machinist.

On the upper deck below the poop are located: the steering gear compartment; a compartment for stores; two insulated compartments for refrigerated meats and provisions; eight bedrooms to accommodate four firemen, three oilers, three wipers, and twelve seamen; a crew's shower room; and a crew's toilet room.

This accommodation is all furnished and equipped in neat substantial comfort. Everything necessary for the convenience and physical well being of the officers and crew is provided. Especial attention has been given to the problem of arrangement, location and equipment to produce maximum comfort combined with safety from fire and with a high degree of sanitation.

All furniture is of metal, all doors are hollow panel metal doors, all plumbing fixtures are of the best quality Crane Company manufacture.

Electric fans and natural ventilation are both employed to force an abundance of fresh air through all the rooms.

To be continued on Part-7

|

See also : First American Arcform Tankers - Part-7