Auke Visser's MOBIL Tankers & Tugs Site | home

The 27,000-Ton Supertanker - Part 5

Sun Ship Completing Sovacs.

Source : Pacific Marine Review, Volume 47, March, 1950

Generators

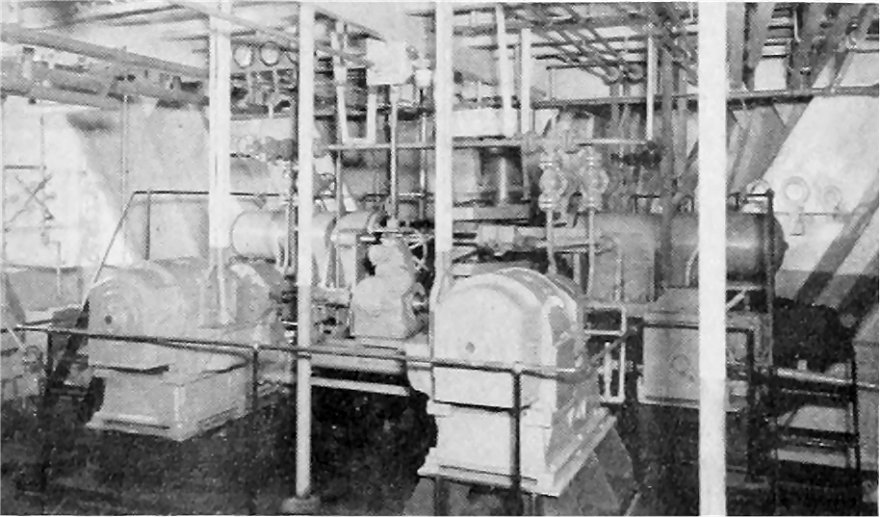

The first two vessels have Crocker-Wheeler main generators driven by Worthington-Moore turbines. The other five vessels have Westinghouse units. Each vessel has two main generators. Each generator is 300 KW, 240 volt D.C., two wire, compound (stabilized shunt) wound, 1,200 RPM. Each generator is driven through single reduction gearing by a multi-stage turbine at 6,097 RPM for the Worthington-Moore and 5.950 for the Westinghouse, taking steam at 585 p.s.i.g. and 790° F. and exhausting to 25 %;" vacuum. The generators have a temperature rating of 40° C. rise at continuous normal load and 55° C. at 25% overload for 2 hours, in 50° C. ambient. They are arranged for parallel operation.

The actual generator load for sea steaming at normal power averaged 195 KW (maximum 204) on the endurance runs of the sea trials.

Each ship has a General Motors diesel-driven generating set. The generator is Delco make, 75 KW, 240 volts D.C., 2-wire, stabilized shunt wound, good for 25% overload for 2 hours. It is driven through a flexible coupling by a 100 HP 6-cylinder, two-cycle, single-acting, mechanical-injection diesel engine 4% x 5", 1800 normal RPM.

There are two 40 KW motor-generator sets for the lighting system, each driven by a 230 volt D.C. motor and delivering 120 volts D.C. Also two A.C. motor-generator sets, each driven by a 230 volt D.C. motor and delivering 5 KVA, 120 volts, single-phase, 60 cycles, with 80 % power factor, for navigation equipment. The M-G sets are G.E. make.

The three generators, switchboard, and M-G sets are located on the generator flat on the port side of the engine room.

Evaporators

The evaporating and distilling plant is of Foster-Wheeler make and is located at the forward starboard corner of the engine room, convenient to the operating platform. It consists of two low-pressure units, and is arranged for automatic operation. Each unit when operating in single effect will produce 6,000 gallons per day of distillate, when supplied with 2,500 pounds of saturated steam per hour at 7.5 p.s.i.a. When operating as a double effect plant, it will produce 6,000 gallons per day when supplied with 1,280 pounds of saturated steam per hour at about 7.5 p.s.i.a. This is based on clean tube conditions, and a brine density of 1.5 thirty-seconds. The distillate is to contain not more than 0.25 grain per gallon. Under emergency conditions the plant, operating double-effect, will produce 12,000 gallons per day when supplied with 1,780 pounds of saturate steam per hour at 20 p.s.i.a

The evaporator feed and circulating pump is centrifugal, of Worthington make, 300 GPM against 40-foot head at 1,750 RPM, driven by a 10 H.P. motor,G.E. The main circulator also discharges to the evaporators and a standby connection is also provided from the general service pump, through an orifice plate. For evaporating raw fresh water, the small (auxiliary) boiler feed pump can be used for evaporator feed. The two evaporator brine pumps, centrifugal, are of Dean make, 12 GPM against 70-foot head at 1,700 RPM, with a 2 H.P. motor, GE. The two evaporator distillate pumps, centrifugal, are of Dean make, 6 GPM against 100-foot

head at 1,750 RPM, with a 2 H.P. motor, GE. Starch feed treatment is provided.

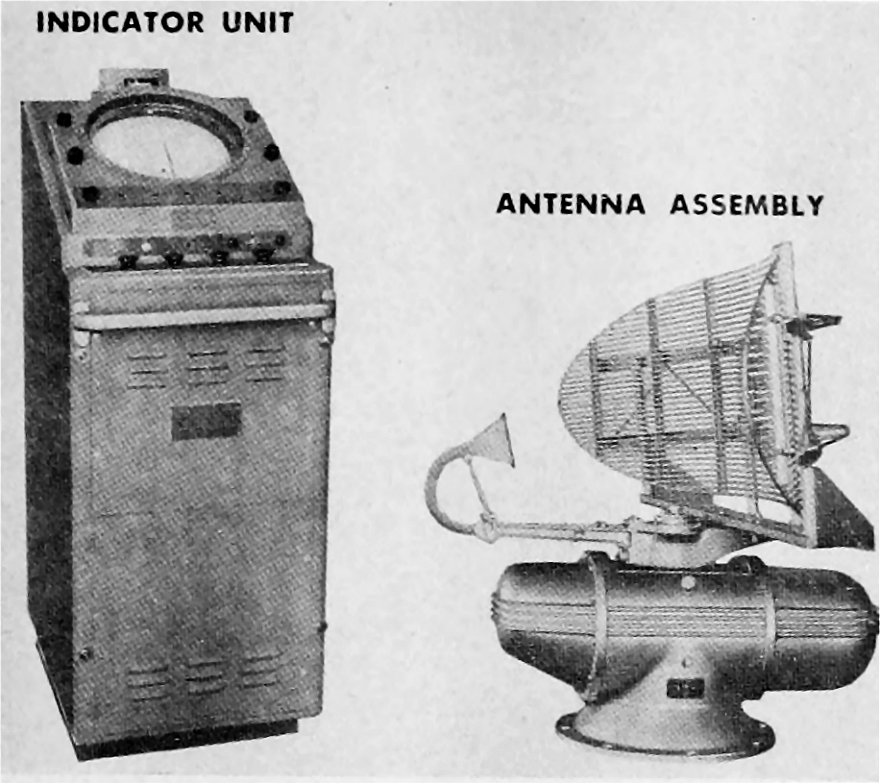

The indicator unit and antenna assembly for Radiomarine Model CR-101-A shipboard radar installed| on fhe Sovac tankers.

Feed System

The boiler feed heating is very simple, representing practically single-stage heating. The condensate pumps discharge through the Davis grease extractors and the inter and after condensers of their respective air ejectors, and through the gland drain condenser, to the deaerating feed water heater. The main feed pumps draw from the deaerator and discharge through the main or auxiliary feed line to the economizers.

There are three centrifugal main feed pumps, of Coffin make. Each is rated at 350 GPM against 750 p.s.i.g. head, at 7,150 RPM, and is direct-driven by a turbine taking steam at 525 p.s.i.g. and 525° F. and exhausting at 10 p.s.i.g. back pressure.

An auxiliary feed pump is also provided, Worthingttin make, 21/4" x 4" vertical triplex plunger type, 30 GPM against 750 p.s.i.g. head at 150 RPM, gear-driven by a G.E. motor, 20 H.P., at 1,750 RPM. This is intended mainly for use in filling the boilers and raising steam.

(Provision for cold-starting is made by a diesel fuel supply line to the fuel service pumps).

The deaerator is of the direct contact feed water heater type, V/orthington make, having a capacity for heating and deaerating 157,260 pounds of feed water per hour when supplied with 20,240 pounds of steam per hour at 10 p.s.i.g. The total heater capacity is 157,500 pounds per hour. The outlet temperature is 240° F. The deaerator is located at the after end of the engine room, at the poop deck level.

Refrigeration

The cold storage rooms for ship's stores are on the upper deck aft. The meat room and chill room each have a capacity of 1,935 cubic feet. The insulation on six hulls is of cork and mineral wool; on the seventh hull it is to be of Foamglass.

There are two main refrigerating machines, freon type, each of 3.26 ton capacity, 1,750 RPM, driven by a 10 HP. motor. Their circulating pump is 25 GPM, 100 p.s.i.g head, 1,750 RPM, with a one H.P. motor, G.E.

The design of the plant and insulation is intended to maintain a temperature of 55° F. in the chill room and 0° F. in the meat room, and to provide for a temperature rise of not more than 9° F. in 6 hours in either room (empty) after the plant is shut down, with an

ambient temperature of 100° F.

The chill room is provided with a 60-gallon scuttle butt and a deodorizer. The meat room contains ice-making trays.

There are two compressor units, each of 0.15 ton capacity, air cooled, with 1/2 H.P. motor, serving two refrigerator boxes of 8 cubic feet each, one in officers pantry aft and one in crew's mess. These boxes are in lieu of the domestic type refrigerators.

The compressor units and accessories are of Carrier make. The machines are located in the steering gear room. Controls are automatic.

There is an identical 0.15 ton compressor unit in the midship fan room and refrigerator box in the officers pantry amidships.

The American Engineering Company steering gear is of ihe electro-hydraulic single opposed ram type with auxiliary hand gear. Valving is arranged so that both power unifs can be used for extra fast steering when desired, wifh control from the pilof house by means of telemotor or Sperry Gyro-Pilot,

Miscellaneous Auxiliaries

The characteristics of the motor-driven auxiliaries (other than those described above) are shown in the accompanying table. The motors included in this tabulation are all 230 volts D.C. and are of GE. make excepting the ventilation fans for the quarters, which

units are furnished by Wing and Ilg. The fan units for engine and boiler room ventilation are axial-flow type.

The fire and butterworth pump is Worthington, horizontal, centrifugal, rated at 400 GPM against 125 p.s.i.g. at 1475 RPM, and 560 GPM against 200 p.s.i.g. at 1750 RPM. It is driven by a Whiton turbine taking steam at 585 p.s.i.g. and 790° F. and exhausting at 10 p.s.i.g. back pressure.

The fuel transfer pump and bilge and ballast pumps in forward pump room are each 12 x 8}/3 x 12" vertical duplex pot valve type, National Transit make, rated at 400 GPM against 125 p.s.i.g. at a piston speed of 70 feet per minute. They take steam from the deck steam line at about 125 p.s.i.g and exhaust to the deck exhaust line at about 10 p.s.i.g

The fuel oil heaters are of Griscom-Russell make and the Butterworth heater and drain cooler are Ross.

The Sun heat balance shows that by using the exhaust from the circulator and feed pump turbines for feed heating and evaporators, the requirement for main turbine extraction is only 540 pounds per hour for normal sea steaming.

Machinery Arrangement

The operating platform is forward of the main turbines, with the control and gauge board against the forward engine room bulkhead. Engineer's workshop (containing a lathe, shaper, drill-press and grinder) and store room is on a flat on the starboard side, at the same level as the generator flat port side. A tranverse watertight bulkhead extending up to the boiler flat (with no door) divides the lower machinery space into forward and after compartments. The screen bulkhead between engine and boiler rooms is also water-tight up to the upper deck, with a hinged W.T. door at the boiler flat.

Special attention has been given to the layout of auxiliaries. piping, floors, gratings and ladders, resulting in a simple. convenient, and clean-looking arrangement.

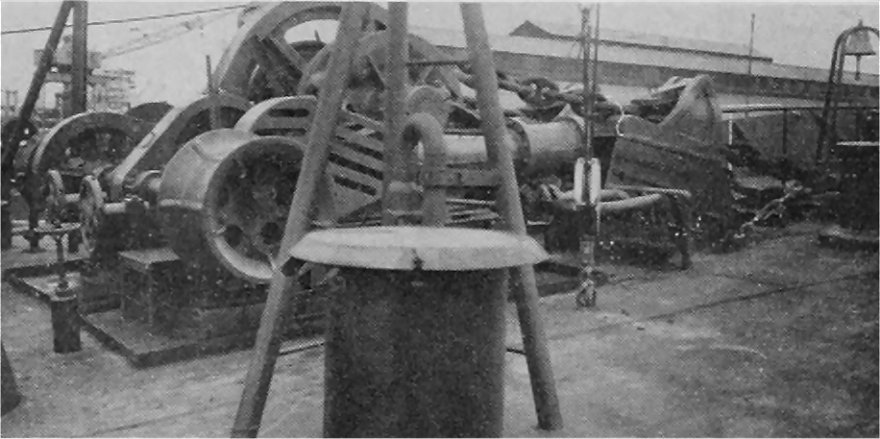

The American Engineering Company spur geared steam windlass is capable of handling two 15,500 lb. anchors and 2 11/16" dielock or Naco chain. Warping heads are on fhe intermediate shaft.

Trials

On each vessel a thorough dock trial is conducted, as well as a six-hour endurance run in open water at full power. On the Sovac Pegasus, standardization runs were also made on the measured course at Delaware Break- water. At 12,500 SHP, the curves show 110.6 RPM and 16.85 knots; at 15,750 SHP, 114.2 RPM and 17.22 knots; all at contract draft. A torsion-meter has been

used on all the trials. On the Some Comet, standardization runs are to be made at a ballast draft of 20-0"

forward and 27-0" aft.

See also : The 27,000-Ton Supertanker - Part 6

|