Auke Visser's MOBIL Tankers & Tugs Site | home

The 27,000-Ton Supertanker - Part 4

Sun Ship Completing Sovacs.

Source : Pacific Marine Review, Volume 47, March, 1950

Cargo System

Each vessel has three main cargo pumps, single-stage centrifugal type, Worthington make, in the pump room, driven through a flexible coupling and gearing by Westinghouse turbines located in the engine room. Each pump has a capacity of 5800 barrels per hour against a discharge head of 125 p.s.i.g., at 1750 RPM, and a capacity of 9,100 barrels per hour against a discharge head of 75 p.s.i.g. at 1750 RPM. The turbines have a corresponding horsepower of 500 at 4540 RPM and operate on desuperheated steam at 525 p.s.i.g. and exhaust back pressure of 10 p.s.i.g. The steam to each turbine is controlled at the pump room entrance. There is no turbine governor other than an overspeed trip. Each drive-shaft is fitted with a special bulkhead stuffingbox and bearing.

The cargo tanks are segregated into three groups: Nos. 1, 2, 3, Nos. 4, 5, 6, and Nos. 7, 8, 9, 10, port. center and starboard. Each group is served by a 16" main suction line, cross-connected in the tanks and in the pump room. Each tank has a 12" suction branch connected to its main line.

Each main pump draws from the main suction lines and discharges to a 16" deck line leading to the hose station amidships. These discharge lines are cross-con- nected, and are arranged to by-pass the pumps for filling and transferring. A 16" drop-line is also provided for filling each group of tanks. Each main pump also draws from port and starboard sea suctions. There is also a

12" stern discharge line. The separation of the piping for the three groups of tanks is accomplished by means of Hamer pipe blinds as well as by the necessary valves.

Each vessel has three stripping pumps, of the rotary type, with reduction gear, National Transit make, in the pump room, driven by General Electric Co. D. C. motors of 75 H.P. each, located in the engine room. Each pump has a capacity of 500 G.P.M. against a discharge head of 125 p.s.i.g., at 300 R.P.M. The motors have controls located in the CO2 room, with extension rods for operation from the pump room entrance.

Each stripping pump draws from the main suction manifold in the pump room, and from the casing of its main cargo pump. The main suction lines have 5" stripper suction branches, one in each tank. There is also an independent 6" stripper line serving the after group of tanks (Nos. 7, 8. 9, 10), with 3 suction branches for these tanks, port, center and starboard.

Each stripping pump discharges to a 4" deck line connecting into its corresponding main line near the hose station.

There is a pump room bilge pump, rotary type, National Transit make, driven by a G. E. Co. D. C. motor of 7 1/2 H. P. in the engine room. The pump has a capacity of 200 G.P.M. against 40 p.s.i.g. discharge head at /120 R.P.M. This pump draws from the pump room bilges and the after cofferdam port and starboard, and discharges to deck and overboard. lts control is arranged similarly to those of the stripping pumps.

The cargo tanks are provided with heating coils of 113 extra heavy pipe, at 125 cubic feet of cargo per square foot of heating coil. The coils are supplied with steam at 150 p.s.i.g. through a separate 6 deck line. The returns lead through a 5" main on deck to an

inspection tank (separate from the one for fuel oil), thence to the atmospheric drain tank and to the engine room bilges.

The cargo pump room is mechanically ventilated by means of two fans, one drawing air through the port

king-post and one fan discharging air through the starboard king-post.

The cargo tanks are ventilated by a 6" pipe from each tank leading through a Vac-Rel valve to 8" and 10 headers at the catwalk, thence up the king-posts. Each group of tanks has a separate vent system.

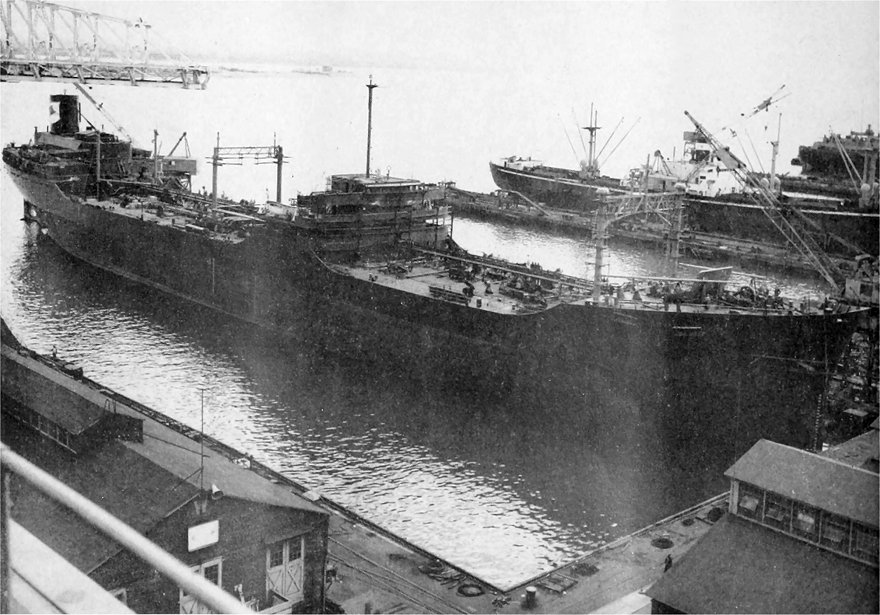

"Sovac Aladdin", at the outfitting dock at Sun Ship.

Deck Gear

There are two king-posts on the forecastle, each with a 5 ton boom serving the forward dry cargo hatch. Two king-posts amidships are fitted with two booms each for handling cargo hose. Two king-posts are also provided at the poop front, each with one boom. All booms are steel.

The only mast is a radar mast on top of the midship house.

The windlass and winches are steam-driven. The Windlass is American Engineering Company make, with two cylinders 12" x 14, suitable for handling the two bower anchors (15,550 pounds each, stockless), and the 2 11/16" chain. The spare bower anchor is stowed in the forward hold. There are five winches: one each on the forecastle deck, on the upper deck forward, on the upper deck at midship king-posts. on upper deck at after kingposts, and on the poop deck. They are American Hoist and Derrick Co. make, 9" x 12, 2-cylinder.

The steering gear is hydro-electric, American Engineering Co. make, with single opposed rams, Rapson slide, and dual power units (50 H. P. motors) driving Hale-Shaw pumps. The telemotor system is hydraulic.

The auxiliary steering gear consists of hand wheels actuating a Hale-Shaw pump and emergency rams.

Accommodations

Each 0fficer has his own stateroom. The two cadets are berthed together. The Captain, first officer, second offcer, radio operator, pilot, and chief and first and second engineers each has a private bath. The other officers share baths between adjoining rooms.

In the officers quarters, the joiner bulkheads are of Marinite, with marine veneer. Marine sheathing is used overhead and on the sides as required. The usual heat insulation is provided. Hopeman Brothers was the joiner sub-contractor on these vessels. The decking is Selbalith. Metal furniture is used, and the accommodations are fire proof throughout with separate exhaust ventilation.

Mechanical ventilation is provided for the quartets, in combination with heating, except that the toilets have steam radiators.

Equipment

Each vessel is equipped with Radiomarine radar, Mackay radio and radio direction finder, and Sperry gyrocompass and automatic steering.

There are four metal lifeboats, each 24 x 8 x 5.75, of 40 person capacity, made by Marine Safety Equipment Corp. Two are oar-propelled and two are motorpropelled with 25 HP Universal engines. The davits and chock fittings are also of Maseco make.

Each ship has a spare propeller (bronze). On the first two vessels this is stowed in the forward dry cargo hold and on the subsequent vessels it is stowed on the upper deck just abaft the rnidship house, starboard.

Each ship also has a spare tailshaft, stowed in the "shaft alley", port side. A portable (riveted) section is provided in the hull to get the tailshaft out and in while on dry dock.

The weights of spare propeller and tailshaft (21.17 and 16 tons respectively) are included in the weight of light ship of these vessels, in determining their deadweight.

Awnings (single) are provided over the navigating bridge deck (except bridge wings), upper bridge deck, boat deck aft and poop deck aft.

The equipment tonnage is 16,704 and the ABS Equipment Number is C-49.

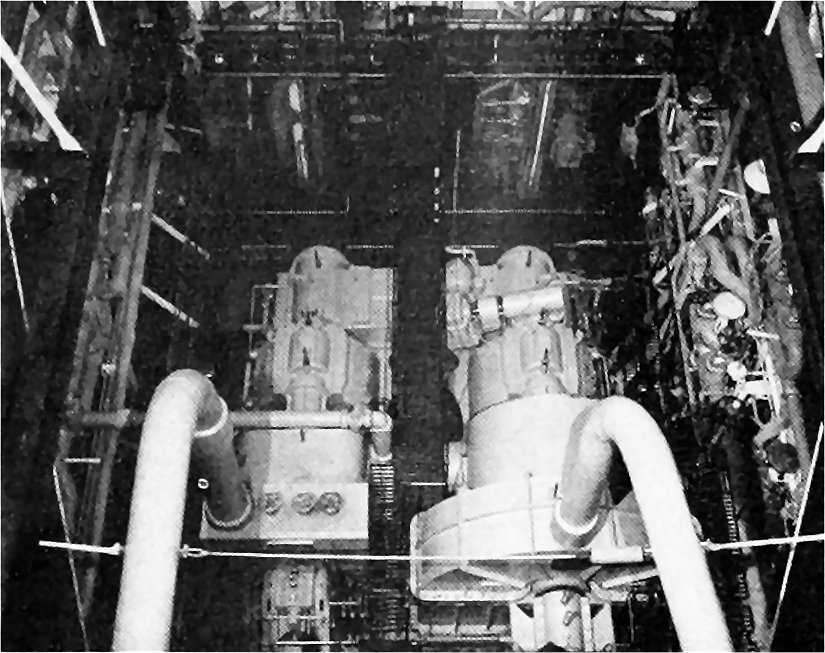

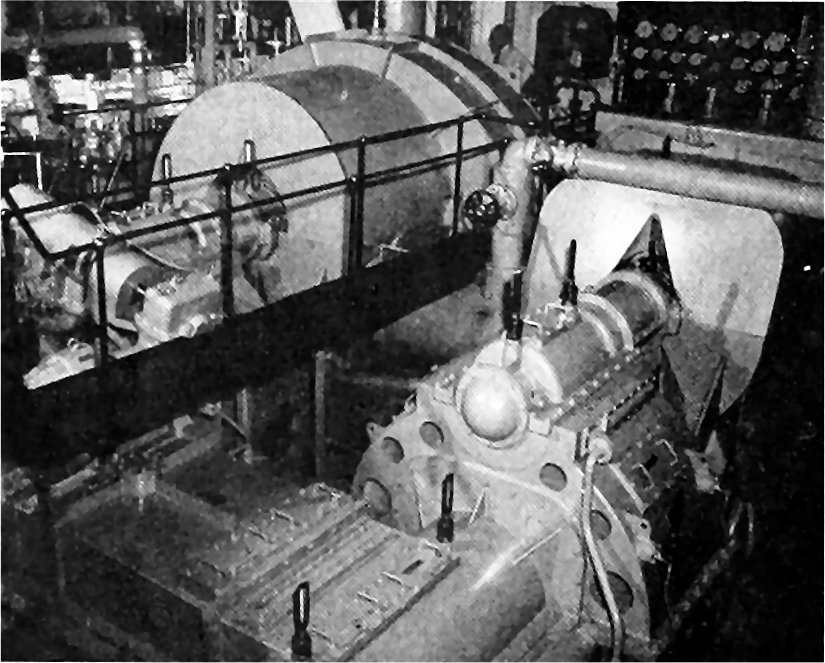

Views of 12,500 shp De Laval geared turbine-driven main propulsion units on Socony-Vacuum Tanker, "Sovac Aladdin," showing high and low pressure turbines, turning gear and instrument panel.

Main Propulsion Unit

The main propelling machinery, built by DeLaval Steam Turbine Company, consists of cross-compound steam turbines and double reduction gears, driving the single-screw shaft. It was designed for 12,500 normal SHP at 112 propeller RPM at contract draft, and 15,750 maximum continuous SHP at 115.7 RPM, with steam at 585 p.s.i.g. and 790° F. at the H.P. steam chest and 28.5 inches Hg. vacuum, for both conditions, while bleeding 10,000 pounds of steam per hour from the cross-over pipe at about 50 p.s.i.a.

The high-pressure turbine, impulse type, runs at 5,644 RPM normal and has ten stages. The low-pressure turbine, single flow impulse type, runs at 5,584 RPM normal and has eight stages, and is combined with a two-stage high-pressure astern element to develop 80 per cent of normal ahead torque at 50 per cent of normal ahead RPM, with a steam flow not greater than that required

for normal ahead operation.

Normally the high-pressure ahead turbine exhausts to the low-pressure ahead turbine which in rurn exhausts to the main condenser. However, emergency connections are provided so that either turbine can be operated alone on high-pressure steam, exhausting to the main condenser.

The high-pressure steam chest is provided with 12 fixed nozzles and 5 hand valves which control 2, 4, and 8 nozzles respectively. The normal SHP condition calls for 20 nozzles open. The ahead, astern, guardian, and governing valves are of Schutte and Koerting Company make, turbine shaft and stage packings are of labyrinth type.

The reduction gearing is double helical.

Flexible couplings of the enclosed, all-metal, gear type are provided between the turbines and their high-speed pinions. The turbine thrust bearings and the propeller thrust bearings are of Kingsbury make. The turning gear is driven by a G.E. motor, D.C., of 10 H.P., with drum control. The lubricating oil system is of the gravity type.

In addition to the normal running-in and shop tests, the main propulsion assembly was given a thorough calibration test at Trenton.

The propeller shaft is 22 1/32 in diameter, fitted with a continuous liner 24 3/4 in diameter at stern bearing, which is lined with lignum vitae.

The propellers are furnished by American Manganese Bronze Company. Each is solid 4-bladed, 20-0" diameter, 16'-10 pitch.

Boilers

Each vessel has two boilers, of Babcock and Wilcox Company make, two drum type, each with an economizer, superheater, and internal desuperheater. (There is no external desuperheater). They are set side by side on a boiler flat in the after part of the machinery space, with the firing aisles forward, and passage between boilers to the after boiler room. The furnace sidewall, roof, and rear wall are water cooled. Single casing is used throughout except for the furnace front wall, which is double cased.

Each boiler is designed for a normal evaporative rate of 52,500 pounds of steam per hour, with a superheater outlet pressure of 600 p.s.i.g. and temperature of 800° F., for a guaranteed efficiency of 87.5 % . The temperature of feed water to economizer is 240°F. The designed overload evaporative rate is 78,750 pounds of steam per hour with a steam temperature of 825°F. Inasmuch as the estimated steaming requirements for all purposes at 12,500 SHP for normal sea conditions is 101,992 pounds per hour, the boiler capacity has considerable margin.

Each boiler has four oil burners, and the vessels are equipped with both mechanical (Iowa) and steam atomizing burners (Y-Jet wide range), both of B. & W. make, which can be used interchangeably.

The heating surface per boiler consists of 7,590 square feet for the boiler proper, 950 for the superheater, and 2,040 for the economizers total 20,760 square feet for both boilers. The furnace volume per boiler is 1,100 cubic feet.

Each vessel has two forced draft blower units, each consisting of a Sturtevant fan in the boiler room, rated at 27,945 C.F.M. against 15" static pressure at 1,750 RPM, driven by a 100 HP. motor, D.C., of G.E. make, located in the engine room. The fans are cross-connected so that either fan alone can serve either or both boilers.

The total draft loss, or air pressure at burner fronts, is about 5" water.

The combustion control is of General Regulator

Company make, electrically operated, and the feed water control is Swartwout. There is no air requirement for sea steaming conditions. The boilers have Bi-Color gauge glasses in the fire room and Yarway remote-reading water level gauges at the boiler room entrance door, visible from the operating platform. A similar gauge for deaerator water level is located with them. The soot-

blowers are of Vulcan make, steam operated.

Condensers

Main and auxiliary condensers are of lngersoll-Rand make, two-pass type. The main condenser is a square section with reheat hotwell and is located athwartships directly under the LP. turbine. It is designed to maintain a vacuum of 28 %" Hg. when condensing 92,000 pounds per hour of steam with 15,200 G.P.M. cooling water at 80°F. with 85 % tube cleanliness and velocity

of cooling water not exceeding 6 feet per second. The cooling surface is 15.600 square feet. The shell is of welded construction, using copper bearing steel plates.

The tube sheets are of Muntz metal and the tubes (Phelps-Dodge) are 5,/4 O.D., No. 16 B.W.O., 70-30 cupro-nickel, expanded both ends.

The main circulator is a vertical unit located in the port forward corner of the engine room. It consists of a Worthington single-stage centrigulgal pump rated at 18,000 G.P.M. against 25-foot head at 660 RPM, gear-driven by a Whiton turbine of 150 H.P. and 5,600 RPM, taking desuperheated steam at 580 p.s.i.g. and exhausting at 10 p.s.i.g back pressure. The pump draws from high and low sea suctions and bilge suction.

The main condensate pumps are in duplicate, Worthington vertical centrifugal, each rated at 250 GPM against 170-foot head at 1,750 RPM. driven by a 20 HP motor, DC, 1750/1150 RPM.

The auxiliary condenser has 5,870 square feet of heating surface. It is of pear-shaped section and is located on the port side. It is designed to maintain a vacuum of 26" Hg. when condensing 52,000 pounds per hour of steam with 4,000 GPM cooling water at 85 % tube cleanliness and 6 feet per second velocity of cooling water. Tubes are American Brass. Otherwise, the construction is as described for the main condenser.

The auxiliary circulating pump is Worthington single-stage vertical centrifugal, rated at 6,500 GPM against 15-foot head and 4.400 GPM against 25-foot head, at 720 RPM. lt is direct-driven by a G.E. motor, DC, 40 HP, 710,- 5-10 RPM. It discharges to the main condenser as well.

The auxiliary condensate pump is Worthington vertical centrifugal, rated at 100 GPM against 170-foot head at 1750 RPM, driven by a motor duplicating those for the main condensate pumps.

The main and auxiliary air ejectors, two each, are Ingersoll-Rand make, multi-stage, with combined intermediate and after condensers.

See also : The 27,000-Ton Supertanker - Part 5

|